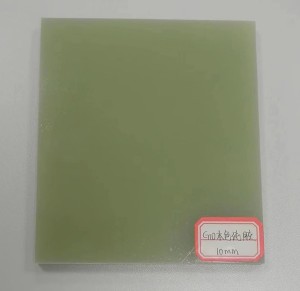

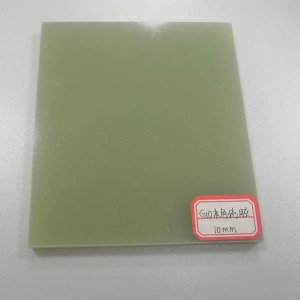

boleng bo phahameng china Natural mmala G10 Epoxy khalase fiber laminated lakane

Tlhaloso ea Sehlahisoa

G10 Epoxy glass fiber laminated sheet (Tlwaelehileng):Sehlahisoa sena se ne se le laminated ke mocheso o phahameng le khatello e phahameng ka lesela la khalase ea elektronike le kenngoeng ka epoxy resin.Ka thepa e phahameng ea mechine le ea dielectric, mocheso o motle le ho hanyetsa maqhubu, hape ka machinability e ntle; Sehlahisoa sena se ka finyella maemo a EU ROHS, se romelloa ka ho pharaletseng ho ea ka boroa-bochabela ho Aisa, Europe, India, joalo-joalo. Ntho ea bohlokoa le ho feta ke hore laminate ena ea G10 ha e na Halogen ebile e na le mollo o thibelang mollo, e leng eco-friendly 'me e ka amoheloa ke limmaraka tsa Europe le Amerika.

G10 ha se lebitso la lintho tse bonahalang, empa ke boemo ba lintho tse bonahalang, lebitso G10 le tsoa tsamaisong ea boemo ba NEMA moo litekanyetso tsa "G" tsa "Glass fiber base"

Ho lumellana le maemo:

Ho ea ka GB/T 1303.4-2009 thermosetting resin industry hard laminates - Karolo ea 4: epoxy resin hard laminates, IEC 60893-3-2-2011 thepa ea ho itšireletsa - lisebelisoa tsa motlakase tsa thermosetting liindasteri tse thata - Karolo ea 3-2 ea litlhaloso tsa motho ka mong EPGC201.

Likaroloana

1.Thepa e phahameng ea mechine;

2.Thepa e phahameng ea dielectric;

3.Ho hanyetsa mongobo o motle;

4.Ho hanyetsa mocheso o motle;

5.Good machinability;

6.Ho hanyetsa mocheso: Kereiti ea B

7.Halogen-mahala le mollo retardant

Index ea Ts'ebetso e ka Sehloohong

E loketse ho sebelisoa ka litlhoko tse phahameng tsa lisebelisoa tsa elektroniki tsa lihlahisoa tse kang FPC reinforcement plate, PCB drilling pad, fiberglass meson, glass fiber board potentiometer carbon film printing, precision tour stars gear grinding (chip), precision test plate, motlakase (motlakase) thepa insulation lula clapboard, insulating plate, transformer insulation board, motor insulation part, jj.

Index ea Ts'ebetso e ka Sehloohong

| NO. | ITEM | THUTO | INDEX BOHLOKO | ||

| 1 | Botenya | g/cm³ | 1.8-2.0 | ||

| 2 | Sekhahla sa ho monya metsi | % | ≤0.5 | ||

| 3 | Matla a ho kobeha a otlolohileng | MPa | ≥340 | ||

| 4 | Matla a kgatello a emeng | MPa | ≥350 | ||

| 5 | Matla a ts'usumetso e ts'oanang (mofuta oa charpy-gap) | KJ/m² | ≥37 | ||

| 6 | Matla a ho kuta a tšoanang | Mpa | ≥34 | ||

| 7 | Matla a tšepe | MPa | ≥300 | ||

| 8 | Matla a motlakase a otlolohileng (ka oli ea 90 ℃ ± 2 ℃) | 1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 9 | Matla a ho senya a tšoanang (ka oli ea 90 ℃ ± 2 ℃) | KV | ≥40 | ||

| 10 | Dielectric dissiption factor (50Hz) | - | ≤0.04 | ||

| 11 | Khanyetso ea Insulation | Tloaelehileng | Ω | ≥5.0×1012 | |

| Ka mor'a ho koloba ka lihora tse 24 | ≥5.0×1010 | ||||

| 12 | Combustibility (UL-94) | Boemo | V-0 | ||