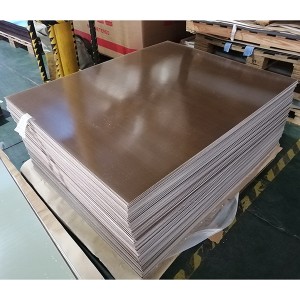

Epoxy Fiberglass Sheet Fr4 Sheet G10 Leqephe la laminate le sa koaloang le nang le Thepa e Ntle ea Mechini le Motlakase

Tlhaloso ea Sehlahisoa

Sehlahisoa sena se ne se le laminated ke mocheso o phahameng le khatello e phahameng ka lesela la elektroniki la glassfiber le kenngoeng ka brominated epoxy resin.E nang le thepa e phahameng ea mochine, thepa ea dielectric le thepa e thibelang malakabe, hape e na le ho hanyetsa mocheso o motle le ho hanyetsa mongobo;

FR-4 ke khoutu ea sehlopha sa lisebelisoa tse hananang le malakabe, e bolelang tlhahiso ea thepa eo lesela la resin le lokelang ho khona ho tima ka boeona kamora ho chesa. Ha se lebitso la lintho tse bonahalang, empa ke boemo ba lintho tse bonahalang. Lebitso FR4 le tsoa ho sistimi ea maemo ea NEMA moo ho'FR'e emetse'sethibela mollo', e tsamaellanang le maemo a UL94V-0. Ka hona, liboto tsa potoloho tsa PCB ka kakaretso, Ho na le mefuta e mengata ea lisebelisoa tsa sehlopha sa FR-4 tse sebelisoang, empa boholo ba tsona ke lisebelisoa tse entsoeng ka Tera-Function epoxy resin e nang le filler le fiber ea khalase.

Ho Ikamahanya le Melao-motheo

Ho ea ka GB/T 1303.4-2009 thermosetting resin industry hard laminates - Karolo ea 4: epoxy resin hard laminates, IEC 60893-3-2-2011 thepa ea ho itšireletsa - lisebelisoa tsa motlakase tsa thermosetting liindasteri tse thata - Karolo ea 3-2 ea litlhaloso tsa motho ka mong EPGC202.

Likaroloana

1.Thepa e phahameng ea mechine;

2.Thepa e phahameng ea dielectric;

3.Good Mechinability

4.Ho hanyetsa mongobo o motle;

5.Ho hanyetsa mocheso o motle;

6.Ho hanyetsa mocheso: Kereiti ea B

7.Thepa e thibelang mollo: UL94 V-0

Kopo

Sehlahisoa sena se sebelisoa haholo e le likarolo tsa sebopeho sa Motor le lisebelisoa tsa motlakase, ho kenyeletsoa mefuta eohle ea switch,lisebelisoa tsa motlakase,Letlapa la matlafatso la FPC,liboto tsa potoloho tse hatisitsoeng ka filimi ea carbon,letlapa la ho phunya komporo,thepa ea hlobo le e qhibilihisang(PCB test lelakabe);mme hape e loketse tlasa tikoloho e metsi leoli ea transformer.

Index ea Ts'ebetso e ka Sehloohong

| NO. | ITEM | THUTO | INDEX BOHLOKO | ||

| 1 | Botenya | g/cm³ | 1.8-2.0 | ||

| 2 | Sekhahla sa ho monya metsi | % | ≤0.5 | ||

| 3 | Matla a ho kobeha a otlolohileng | MPa | ≥340 | ||

| 4 | Matla a kgatello a emeng | MPa | ≥350 | ||

| 5 | Matla a ts'usumetso e ts'oanang (mofuta oa charpy-gap) | KJ/m² | ≥37 | ||

| 6 | Matla a ho kuta a tšoanang | Mpa | ≥34 | ||

| 7 | Matla a tšepe | MPa | ≥300 | ||

| 8 | Matla a motlakase a otlolohileng (ka oli ea 90 ℃ ± 2 ℃) | 1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 9 | Matla a ho senya a tšoanang (ka oli ea 90 ℃ ± 2 ℃) | KV | ≥40 | ||

| 10 | Dielectric dissiption factor (50Hz) | - | ≤0.04 | ||

| 11 | Khanyetso ea Insulation | Tloaelehileng | Ω | ≥5.0×1012 | |

| Ka mor'a ho koloba ka lihora tse 24 | ≥5.0×1010 | ||||

| 12 | Combustibility (UL-94) | Boemo | V-0 | ||