3250 Epoxy Fiberglass Laminated Sheet(G11-H)

Tataiso ea Sehlahisoa

Lisebelisoa tsa 3250 ke phekolo ea lik'hemik'hale tsa motlakase tse entsoeng ka motlakase tse entsoeng ka alkali-free fiberglass tse matlafalitsoeng, tse kopantsoeng le TG epoxy resin e phahameng. E na le matla a phahameng a mochine tlas'a mocheso o tloaelehileng, e ntse e na le matla a matla a mochine, thepa e ntle ea motlakase tlas'a tikoloho e omileng le e metsi, e ka sebelisoa tikoloho e mongobo le transformer oil.It ke ea sehlopha sa H mocheso ho hanyetsa insulating thepa.

Ho lumellana le litekanyetso

TS EN 60893-3-2-2009 IEC 60893-3-2-2009 lisebelisoa tsa insulating tsa motlakase oa thermosetting resin - Karolo ea 4: Li-laminate tse thata tsa epoxy resin - Karolo ea 3-2 ea lisebelisoa tsa motho ka mong Setšoantšo sa EPGC308.

Kopo

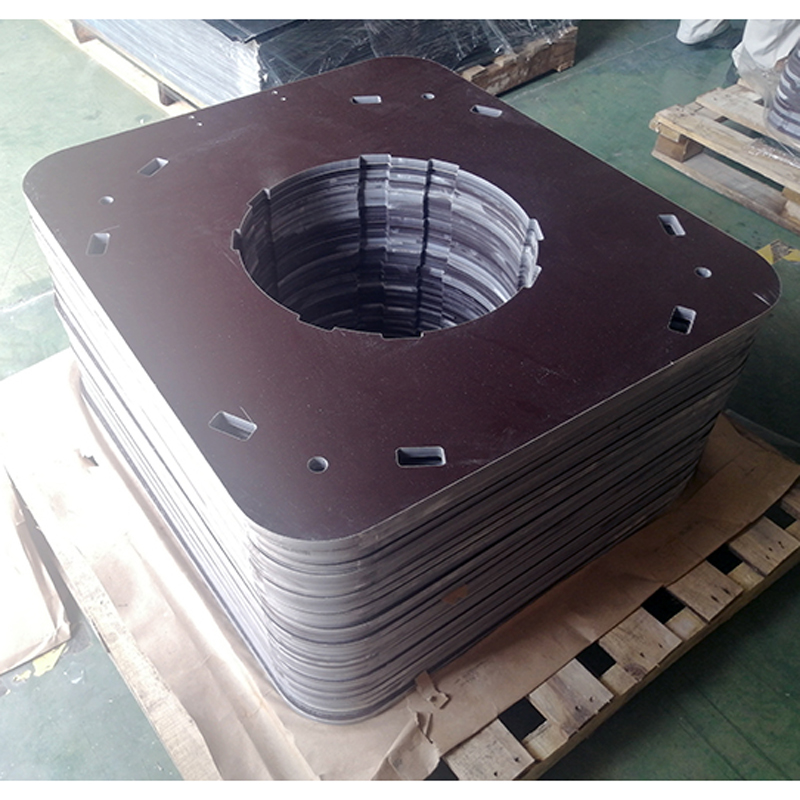

E loketse li-motor tsa sehlopha sa 180 (H), li-motor tse kholo joalo ka li-slot wedges le lisebelisoa tsa motlakase tse phahameng haholo joalo ka sephetho sa ho thibela mocheso,

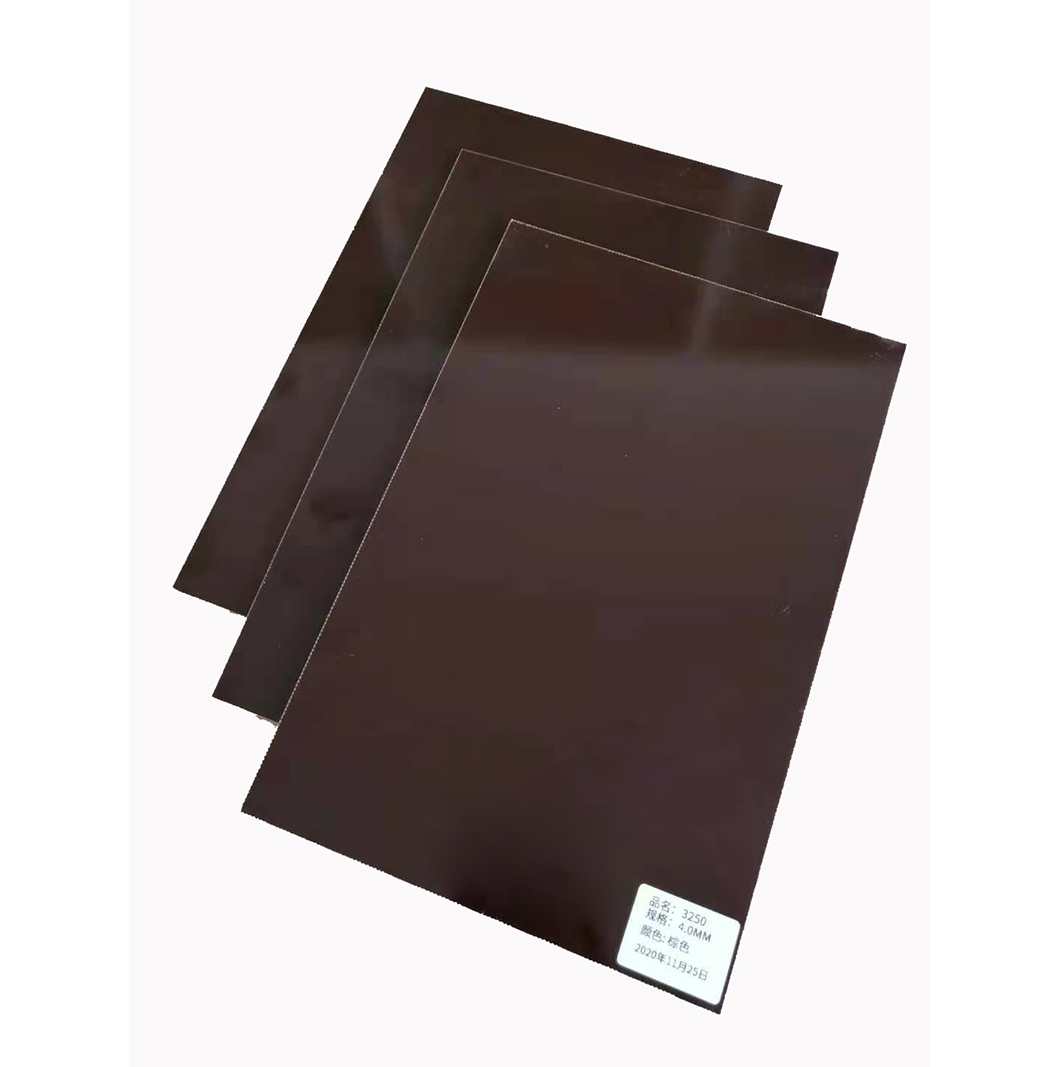

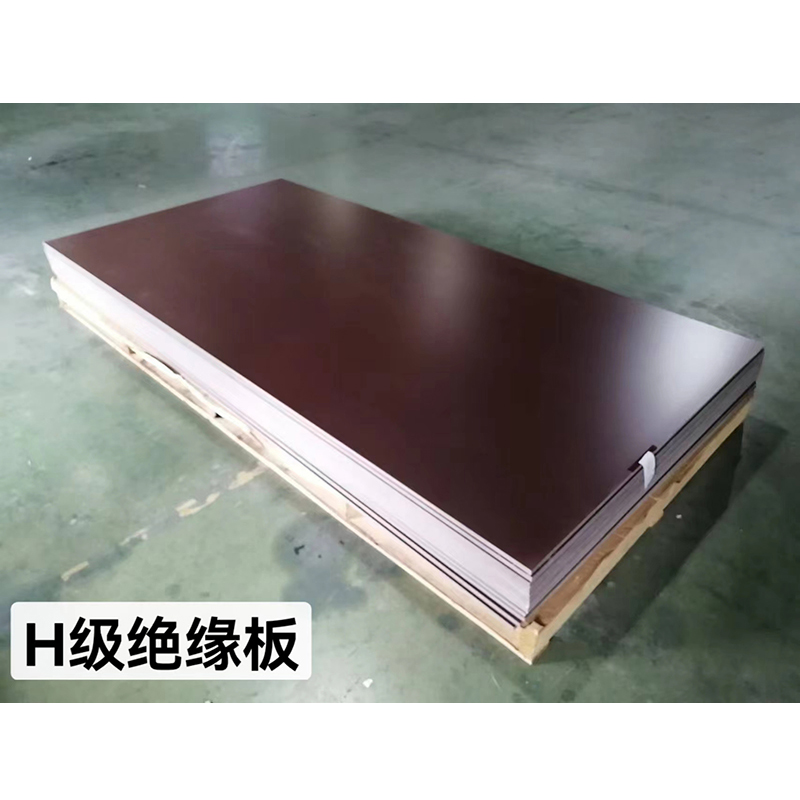

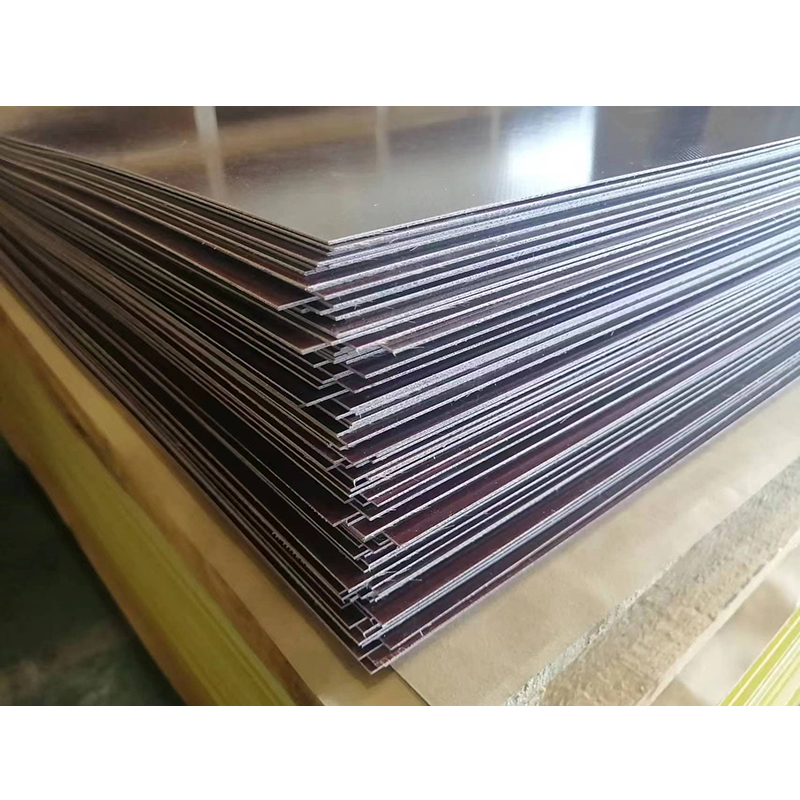

Litšoantšo tsa lihlahisoa

Letsatsi le ka Sehloohong la Tekheniki(Tobetsa mona ho khoasolla tlaleho ea tlhahlobo ea motho oa boraro)

| Ntho | Thepa | Yuniti | Boleng bo Tloaelehileng | Boleng bo Tlwaelehileng | Mokhoa oa Teko |

| 1 | Flexural matla perpendicular to laminations(MD,23℃±2℃) | MPa | ≥380 | 644 | GB/T 1303.2 |

| 2 | Flexural matla perpendicular to laminations(MD,180℃±2℃) | MPa | ≥190 | 320 | |

| 3 | Matla a matla a Charpy a tšoana le laminations(Notched,MD) | kJ/m2 | ≥37 | 114 | |

| 4 | Matla a tsitsipano (MD) | MPa | ≥300 | 402 | |

| 5 | Matla a hatellang a perpendicular ho laminations(23℃±2℃) | MPa | ≥380 | 640 | |

| 6 | Matla a hatellang a perpendicular ho laminations(180℃±2℃) | MPa | ≥190 | 378 | |

| 7 | Matla a motlakase a ipapisitse le laminations (ho 90 ℃ ± 2 ℃ ho 25 # oli ea transformer, tlhahlobo ea mohato ka mohato, Φ25mm/Φ75mm cylindrical electrode) | kV/mm | ≥14.2 | 19.3 | |

| 8 | Ho senyeha ha motlakase ho tsamaisana le laminations (ho 90 ℃ ± 2 ℃ ho 25 # oli ea transformer, tlhahlobo ea mohato ka mohato ea 20s, Φ130mm/Φ130mm poleiti ea motlakase) | kV | ≥45 | >100 | |

| 9 | Tumello e Lekanyelitsoeng(1MHz) | _ | ≤5.5 | 5.20 | |

| 10 | Dielectric dissipation factor(1MHz) | _ | ≤0.04 | 0.019 | |

| 11 | Ho hanyetsa ho itšireletsa ka mor'a ho qoelisoa ka metsing (MD, li-electrode tsa taper pin, lekhalo la 25.0mm) | Ω | ≥5.0 x1010 | 4.9x1014 | |

| 12 | Ho monya metsi | mg | ≤22 | 18.00 | |

| 13 | Botenya | g/cm3 | 1.7-2.0 | 1.93 | |

| 14 | Index ea mocheso | ℃ | _ | 180 ℃ | |

| 15 | TG | ℃ | _ | 200℃±5℃ |

LBH

Q1: Na u khoebo ea k'hamphani kapa moetsi?

Re baetsi ba ka sehloohong ba motsoako oa motlakase oa motlakase, re 'nile ra kopanela ho moetsi oa thermoset rigid composite ho tloha 2003.Boemo ba rona ke 6000TONS / selemo.

Q2: Mehlala

Mehlala ke mahala, o hloka feela ho lefella tefiso ea ho tsamaisa thepa.

Q3: U tiisa joang boleng ba tlhahiso ea bongata?

Bakeng sa ponahalo, boholo le botenya: re tla etsa tlhahlobo e felletseng pele re paka.

Bakeng sa boleng ba ts'ebetso: Re sebelisa foromo e tsitsitseng, 'me e tla ba tlhahlobo ea kamehla ea lisampole, re ka fana ka tlaleho ea tlhahlobo ea sehlahisoa pele re romelloa.

Q4: Nako ea ho fana

E itšetlehile ka palo ea taelo.Ka kakaretso, nako ea ho fana e tla ba matsatsi a 15-20.

Q5: Sephutheloana

Re tla sebelisa pampiri e entsoeng ka matsoho ho paka holim'a plywood pallet.haeba u na le litlhoko tse khethehileng tsa sephutheloana, re tla paka joalo ka tlhoko ea hau.

Q6: Tefo

TT, 30% T/T esale pele ,ho leka-lekana pele ho romelloa.Re boetse re amohela L/C.