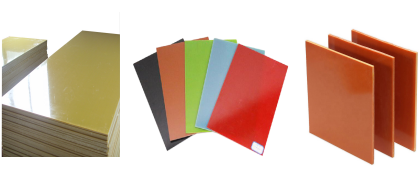

3240 Epoxy phenol aldehyde Glassfiber laminated sheet

Tlhaloso ea Sehlahisoa

3240 Epoxy phenolic glass fiber laminated sheet(Kereiti A):Sehlahisoa sena ke sehlahisoa sa laminated se entsoeng ka lesela la khalase le se nang motlakase la alkali le kentsoeng ka epoxy phenolic resin ka ho tobetsa ho chesang.Thermostablity ke grade B. E na le thepa e ntle ea mechine le ea dielectrical.,

E sebetsa libakeng tsa mechini, tsa motlakase, tsa elektroniki, tsa motlakase le tse ling. E boetse e sebelisoa ha ho sebetsoa likarolo tsa insulating, 'me e sebetsoa ka mefuta eohle ea likarolo tsa insulating le lisebelisoa tse sireletsang likarolo tsa sebopeho, tse ka sebelisoang maemong a mongobo a tikoloho le oli ea transfoma.

3240 Epoxy phenolic glass fiber laminated sheet(Kereiti ea B):Sehlahisoa sena ke sehlahisoa sa laminated se entsoeng ka lesela la khalase le se nang motlakase la alkali le kenngoeng ka epoxy phenolic resin ka ho tobetsa ho chesang.Hobane 3240-B e theko e tlaase ho feta 3240-A 'me e na le ts'ebetso e ntle, e tloaelehile haholo' marakeng. Ho fumana lintlha tse ling, ka kopo ikopanye le barekisi ba rona.

Ho Ikamahanya le Melao-motheo

Ho ea ka GB/T 1303.4-2009 thermosetting resin industry hard laminates - Karolo ea 4: epoxy resin hard laminates, IEC 60893-3-2-2011 thepa ea ho itšireletsa - lisebelisoa tsa motlakase tsa thermosetting liindasteri tse thata - Karolo ea 3-2 ea litlhaloso tsa motho ka mong EPGC201.

Likaroloana

1.Lintho tse ntle tsa mochini;

2.Lintho tse ntle tsa dielectrical;

3.Ho hanyetsa mongobo, ho loketse tlas'a

tikoloho e metsi le oli ea transformer.

4.Good machinability thepa

5.Ho hanyetsa mocheso: Kereiti ea B

Kopo

1) E sebelisoa ho litlhoko tsa ts'ebetso ea mochini oa enjene e phahameng, lisebelisoa tsa motlakase le likarolo tsa sebopeho sa insulate

2) ICT, ITE e laola ts'ebetso ea likarolo tsa ho kenya letsoho, lisebelisoa tsa liteko, li-keypads tsa silicon

3) poleiti ea ho lokisa, plywood ea hlobo, li-countertops grinding plate, mechini ea ho paka, kama, joalo-joalo.

Index ea Ts'ebetso e ka Sehloohong

| NO. | ITEM | THUTO | INDEX BOHLOKO | ||

| 1 | Botenya | g/cm³ | 1.8-2.0 | ||

| 2 | Sekhahla sa ho monya metsi | % | ≤0.5 | ||

| 3 | Matla a ho kobeha a otlolohileng | MPa | ≥340 | ||

| 4 | Matla a kgatello a emeng | MPa | ≥350 | ||

| 5 | Matla a ts'usumetso e ts'oanang (mofuta oa charpy-gap) | KJ/m² | ≥33 | ||

| 6 | Matla a matla a tšoanang (mokhoa oa beam ea cantilever) | KJ/m² | ≥34 | ||

| 7 | Matla a ho kuta a tšoanang | Mpa | ≥30 | ||

| 8 | Matla a tšepe | MPa | ≥200 | ||

| 9 | Matla a motlakase a otlolohileng (ka oli ea 90 ℃ ± 2 ℃) | 1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 10 | Matla a ho senya a tšoanang (ka oli ea 90 ℃ ± 2 ℃) | KV | ≥35 | ||

| 11 | Dielectric dissiption factor (50Hz) | - | ≤0.04 | ||

| 12 | Khanyetso ea Insulation | Tloaelehileng | Ω | ≥5.0×1012 | |

| Ka mor'a ho koloba ka lihora tse 24 | ≥5.0×1010 | ||||