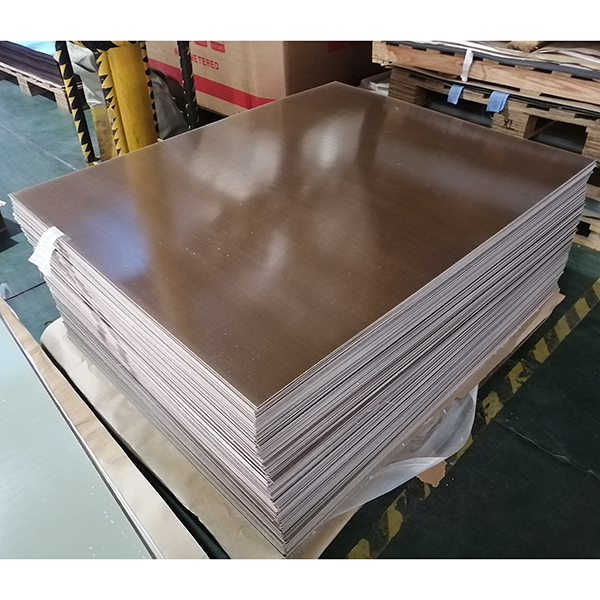

3233 NEMA G5 Melamine khalase lesela laminate loketseng bakeng sa arc manganga lintho tse bonahalang ka fapoha

Tlhaloso ea Sehlahisoa

Sehlahisoa sena ke letlapa la laminated le entsoeng ka lesela la khalase le sa lefelloeng la alkali le kenngoeng ka melamine resin ka ho tobetsa ho chesang. E na le khanyetso e ntle ea arc le thepa e itseng ea dielectric le thepa e thibelang malakabe. E ka sebelisoa e le lisebelisoa tsa ho hanyetsa arc ho li-switches, likarolo tsa sebopeho sa lisebelisoa tsa motlakase le lisebelisoa tsa ho itšehla thajana bakeng sa lisebelisoa tsa motlakase.

Likaroloana

1.Botsitso bo botle ba motlakase tlas'a mongobo o phahameng;

2.Matla a phahameng a mochine tlas'a mocheso o phahameng;

3.Ho hanyetsa mongobo;

4.Ho hanyetsa mocheso;

5. Ho hanyetsa mocheso: Kereiti ea F

Ho lumellana le maemo:

Ho ea ka GB/T 1303.4-2009 thermosetting resin industrial hard laminates - Karolo ea 4: epoxy resin hard laminates.

Ponahalo: bokaholimo bo lokela ho ba bo bataletseng, bo se na li-bubble, likoting le masoba, empa liphoso tse ling tse sa amang ts'ebeliso li lumelletsoe, joalo ka: li-scratches, indentation, stains le matheba a 'maloa.

Kopo:

E loketse mefuta eohle ea enjene, lisebelisoa tsa motlakase, tsa elektroniki le tse ling.

Index ea Ts'ebetso e ka Sehloohong

| NO. | ITEM | THUTO | INDEX BOHLOKO | ||

| 1 | Botenya | g/cm³ | 1.8-2.0 | ||

| 2 | Sekhahla sa ho monya metsi | % | ≤3.0 | ||

| 3 | Matla a ho kobeha a otlolohileng | MPa | ≥200 | ||

| 4 | Matla a ts'usumetso e ts'oanang (mofuta oa charpy-gap) | KJ/m² | ≥25 | ||

| 5 | Matla a motlakase a otlolohileng (ka oli ea 90 ℃ ± 2 ℃) | 1mm | KV/mm | ≥7.0 | |

| 2mm | ≥5.4 | ||||

| 3mm | ≥5.0 | ||||

| 6 | Matla a ho senya a tšoanang (ka oli ea 90 ℃ ± 2 ℃) | KV | ≥15 | ||

| 7 | Khanyetso ea Insulation | Tloaelehileng | Ω | ≥1.0×1010 | |

| Ka mor'a ho koloba ka lihora tse 24 | ≥1.0×108 | ||||

| 8 | Ho chesa | Boemo | V-0 | ||